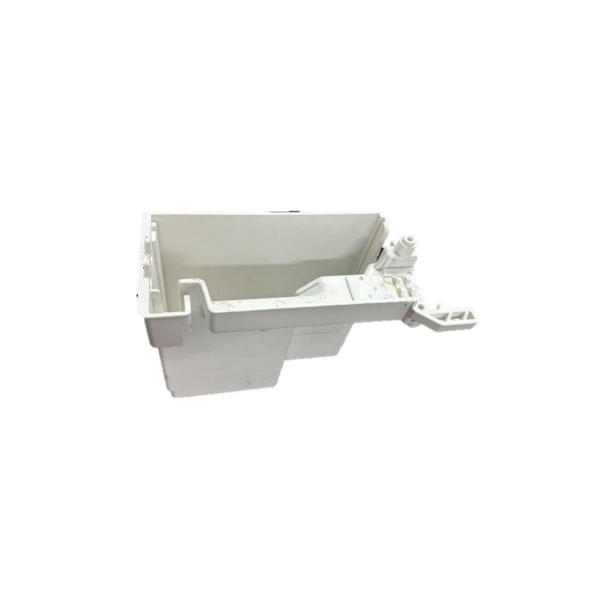

The characteristics of precision molds and their differences from ordinary molds

What are the differences between precision molds and general moldsSix characteristics of precision mold forming:1、 The standard accuracy of the product is high, and the public service is small, that is, there is a high-precision standard boundary;2、 The repeatability accuracy of the product is req

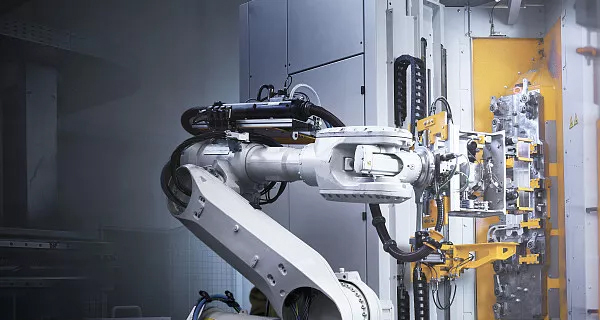

【View Details】